Overview

The Programs in Woodworking Skills Education provides a unique opportunity to join an industry-integrated program, aligning with the Swiss Dual Vocational Education system. This unique approach ensures that learners get hands-on training and are industry-ready after graduation. The program is mapped out to develop specialists in creating woodworking projects including furniture, interior fittings, cabinets, tables, and modular kitchens and collaborating seamlessly.

Programs Offered

Crafting Wood with Hand Tools & Handy Machine

This course equips participants with practical skills in woodworking using hand tools and portable machines. Graduates will be capable of interpreting technical drawings, creating wood joints, operating machinery safely, and completing independent woodworking projects.

Duration: 18 Days

Eligibility Criteria:

- Prior experience or basic knowledge in woodworking or carpentry is preferred.

- Passion for hands-on learning and craftsmanship.

Explore Course

CNC Machinist in Furniture Industry

This short course equips learners with essential skills to operate and program CNC machines for woodworking applications. Graduates will gain hands-on experience in production with CNC machining, ensuring efficiency and precision in wood processing.

Duration: 12 Days

Eligibility Criteria:

- Working Experience in Furniture Industry

Explore Course

Furniture Maker Foreman

This short course equips experienced furniture makers with the technical, managerial, and leadership skills needed to oversee workshop operations, lead production teams, and ensure efficient, high-quality output. Graduates will be trained to plan projects, manage resources, enforce safety standards, and supervise teams in a professional furniture-making environment.

Duration: 12 Days

Eligibility Criteria:

- Working Experience in Furniture Industry

Explore Course

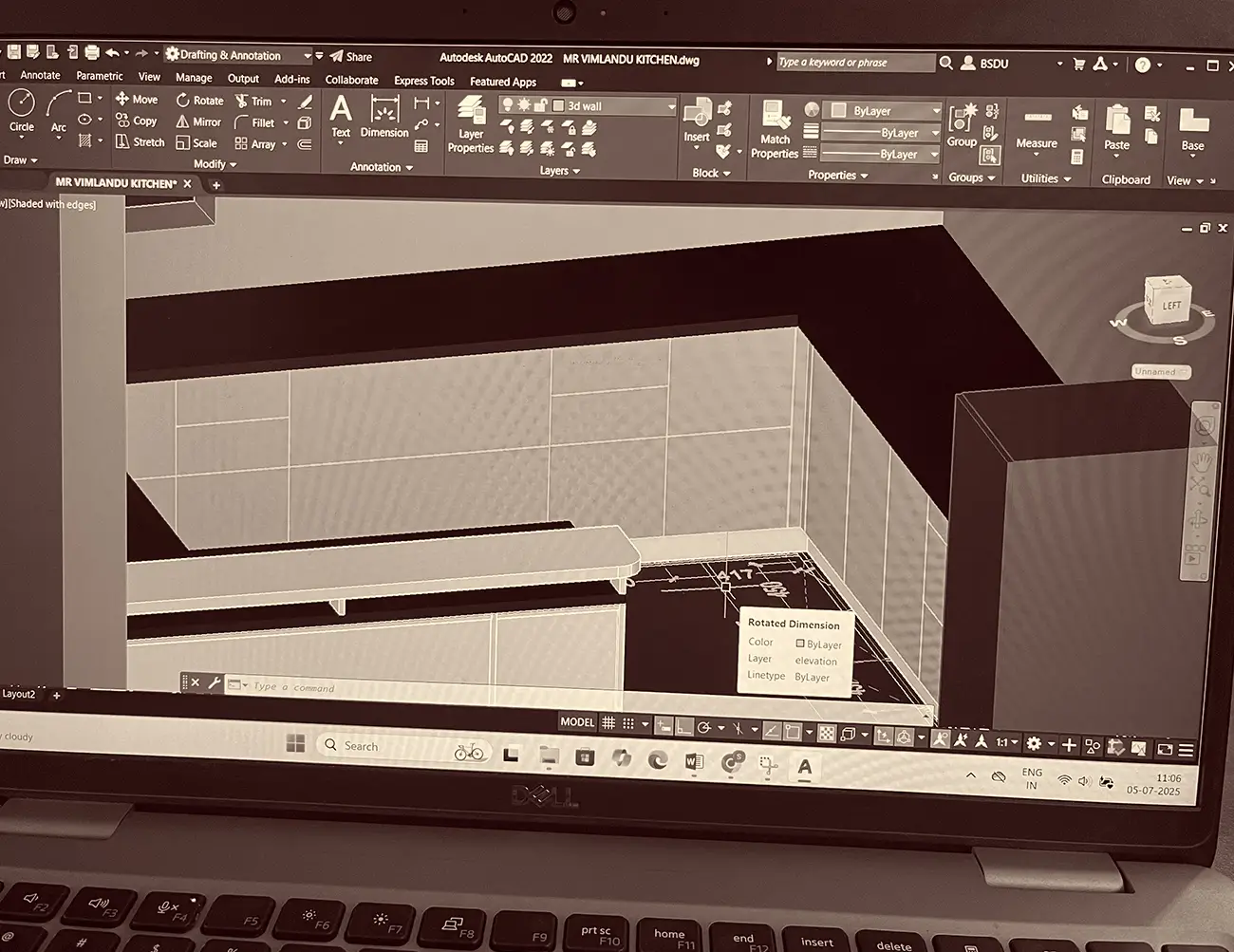

Product development and design using Auto CAD

This short course equips learners with essential skills to use Auto CAD to create furniture specific drawing, they will gain hands-on experience on furniture specific drawing to gain proficiency in 2D drafting, Isometric drafting and 3D modelling and production drawing.

Duration: 12 Days

Eligibility Criteria:

- Working Experience in Furniture Industry.

Explore Course

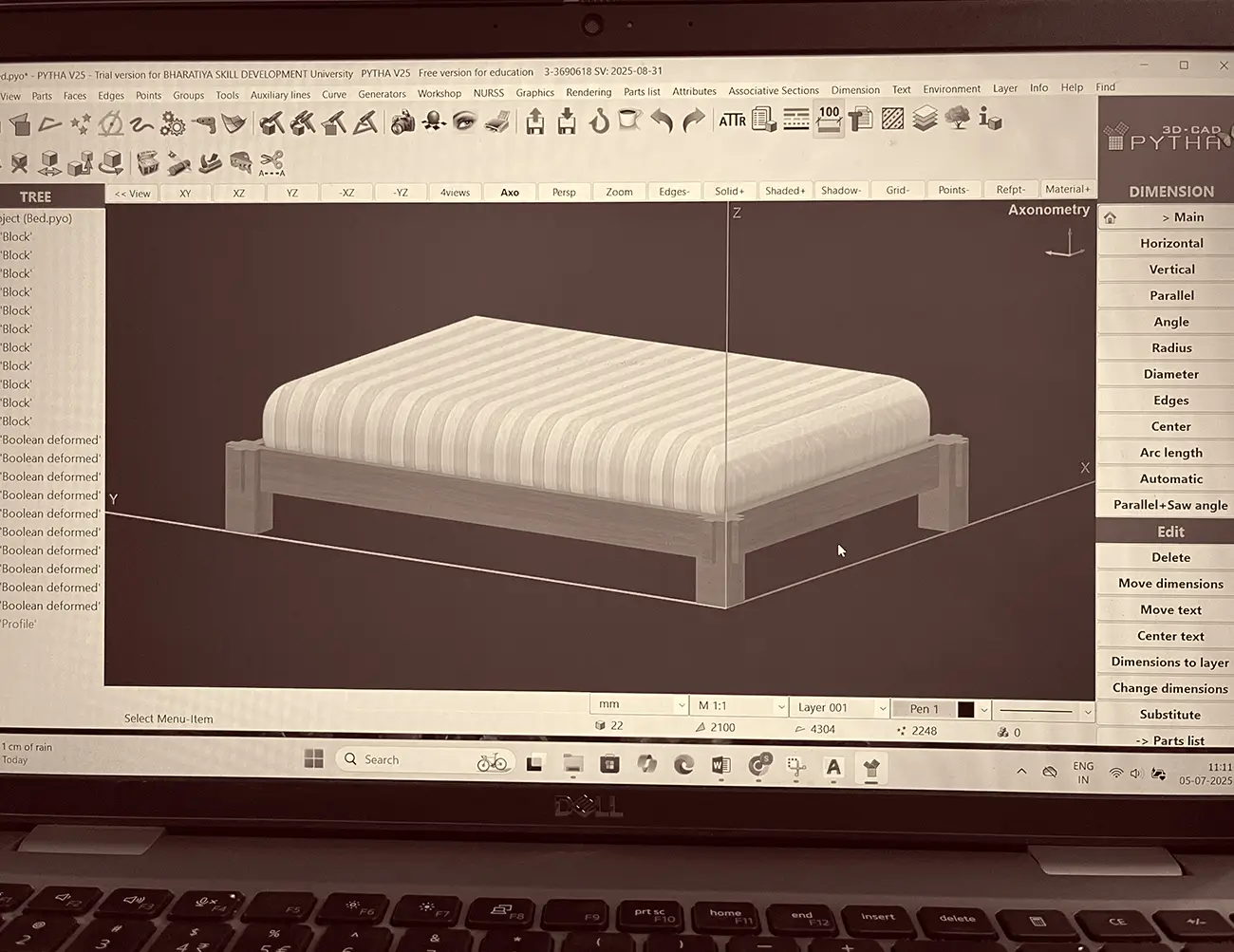

Product development and design using PYTHA

This short course equips learners with essential skills to use Pytha software to create furniture specific drawing, they will gain hands-on experience to gain proficiency in 3D modelling, creating BOM, and detailed production drawing.

Duration: 12 Days

Eligibility Criteria:

- Working experience in Furniture Industry.

Explore Course

CNC Machinist in Furniture Industry

This short course equips learners with essential skills to operate and program CNC machines for woodworking applications. Graduates will gain hands-on experience in production with CNC machining, ensuring efficiency and precision in wood processing.

Key Competencies:

- Wood and Wood based panels knowledge– Describe wood and wood based panels, properties behaviour and application.

- CNC Programming – Being able to make the programmes on CNC Router.

- CAD to CAM File Transfer – Seamlessly convert designs into machine-ready files.

- CNC Machine Operation – Setup & run CNC routers safely.

- Router Bit Selection & Usage – Choose appropriate bits for different woodworking tasks.

- Troubleshooting & Problem-Solving – Diagnose and resolve common CNC machining issues.

Career Pathways:

- CNC Operator (Woodworking Industry)

- CNC Programmer

Eligibility Criteria:

Working Experience in Furniture Industry

| Module | Sub-module & Day(s) | |

|---|---|---|

| Fundamental of Wood & CNC Router |

- Wood & Wood Based Panels

- Fundamentals of CNC Router >

(1 Day)

|

|

| Understand the CNC router |

- Machine introduction

- Machine Setup - Machine Software >

(1 Day)

|

|

| Understanding of Blueprint & File Transfer |

- Drawing Reading

- Transfer CAD file to CAM file >

(2 Days)

(1 Day) |

|

| Basics of machine programming |

- Machine Warm-up

- Basic Programming - Tools changing Process >

(2 Days)

|

|

| Advance Operations on CNC Router |

- Operating CNC Machine on Advance Programming

- Troubleshooting & Problem Solving >

(3 Days)

|

|

| Final Project |

- Project Execution & Showcase

(2 Days)

|

|

Two weeks of training. That is, from 9.00 a.m. to 5.00 p.m., with a 15-minute morning break, an hour-long lunch break, and a 15-minute afternoon tea break. Classes run from Monday to Saturday.

The course follows a hands-on, competency-based approach, combining classroom instruction with practical training on industry-standard Felder CNC machines. The program begins with theoretical foundations, covering the fundamentals of wood and wood based panels, CAD/CAM software, and CNC programming in interactive classroom sessions. then Learners transition it to applied training on Felder CNC routers to practice machine setup, and precision cutting. Under expert supervision, participants troubleshoot real-world scenarios—from bit selection to fixing programming errors—ensuring they gain job-ready skills in a production-like environment.

Certification includes a final project where learners produce a finished wood product.

Cost per participant or group pricing.

Furniture Maker Foreman

This short course equips experienced furniture makers with the technical, managerial, and leadership skills needed to oversee workshop operations, lead production teams, and ensure efficient, high-quality output. Graduates will be trained to plan projects, manage resources, enforce safety standards, and supervise teams in a professional furniture-making environment.

Key Competencies:

Graduates will be prepared to lead teams, streamline production, and deliver high-quality furniture projects on time and within budget—bridging the gap between craftsmanship and management.

- Plan and execute projects by interpreting designs, selecting materials, and managing budgets and timelines.

- Optimize workshop operations through inventory control, equipment maintenance, and lean production methods.

- Lead and delegate tasks effectively by aligning teams, resolving conflicts, and ensuring clear communication.

- Enforce safety and compliance with OSHA standards, first aid readiness, and environmental regulations.

Career Pathways:

- Furniture Workshop Foreman / Supervisor

- Production Manager (Custom Furniture & Joinery)

- Site Supervisor (High-End Carpentry & Fit-Outs)

- Cost Estimator – Furniture Manufacturing

- Self-Employed Workshop Owner

Eligibility Criteria:

Working Experience in Furniture Industry

| Module | Sub-module & Day(s) | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Industrial Practices |

- Responsibilities & Expectations

- Project Planning & Workflow Optimization - Overview of Hand tools & Measuring tools - Understanding Blueprints & Work Orders >

(2 Days)

|

|||||||||||||||||||||

| Shop floor Management |

|

|||||||||||||||||||||

| Workplace Readiness |

- Medical assistance & first aid kit

- Electrical Competence - Soft skills >

(2 Days)

|

|||||||||||||||||||||

| Project |

- Practice on Furniture Specific Drawing to create BOQ

>

(1 Day)

|

|||||||||||||||||||||

The program is planned for 96 hours. The lessons for Furniture Maker Foreman span two weeks of training. That is, from 9.00 a.m. to 5.00 p.m., with a 15-minute morning break, an hour-long lunch break, and a 15-minute afternoon tea break. Classes run from Monday to Saturday.

The training methodology will focus on practical, hands-on experiences, with a strong emphasis on real-world applications. Students will engage in live projects, machine operation practice, blueprint reading, and tool usage. Training will include safety drills, workshops, and team-based tasks to build problem-solving and collaboration skills.

Students will be awarded a certificate for developing a furniture-specific product, applying all the skills learned during the training.

Cost per participant or group pricing.

Crafting Wood with Hand Tools & Handy Machine

This course equips participants with practical skills in woodworking using hand tools and portable machines. Graduates will be capable of interpreting technical drawings, creating wood joints, operating machinery safely, and completing independent woodworking projects.

Key Competencies:

- Apply workplace safety and use of PPE

- Measure, mark, and cut wood accurately

- Create various wood joints (e.g., dovetail, mortise & Tenon)

- Operate machines: circular saw, router, planer, etc.

- Read and interpret engineering drawings

- Install basic hardware fittings

- Repair and maintain wooden structures

- Complete independent woodworking projects

Career Pathways:

- Product development and design using Auto CAD

- Woodworking Technician

- Furniture Maker

- Machine Operator (Wood Industry)

- Carpentry Workshop Assistant

- Repair & Maintenance Artisan

- Self-employed Craftsman

Eligibility Criteria:

- Prior experience or basic knowledge in woodworking or carpentry is preferred.

- Passion for hands-on learning and craftsmanship.

| Module | Sub-module & Day(s) | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Industrial Practices |

- Workplace Safety

- Wood Science - Engineering Drawing >

(1 Day)

|

||||||||||||||||||||||||

| Hand Tools |

|

||||||||||||||||||||||||

| Handy Machines |

|

||||||||||||||||||||||||

| Restructure and repairing |

(1 Day)

|

||||||||||||||||||||||||

| Project |

(4 Days)

|

||||||||||||||||||||||||

Product development and design using Auto CAD

This short course equips learners with essential skills to use Auto CAD to create furniture specific drawing, they will gain hands-on experience on furniture specific drawing to gain proficiency in 2D drafting, Isometric drafting and 3D modelling and production drawing.

Key Competencies:

- Wood and Wood based panels knowledge– Understand wood and wood based panels properties behaviour and application.

- Participants will learn the Fundamentals of Engineering Drawing and Projections.

- Auto CAD Software Proficiency – Learn the drawing, editing utilities and various useful commands to create the furniture specific 2D and 3D drawing.

- Convert the Dwg file to machine readable formats such as DXF to transfer it to CNC Router.

Career Pathways:

- Draughtsman

- Designer and 3D visualizer

Eligibility Criteria:

Working Experience in Furniture Industry.

| Module | Sub-module & Day(s) | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Industrial Practice |

- Fundamentals of wood and wood based panels

- Fundamentals of Drawing and Projections >

(1 Day)

|

|||||||||||||||||||||

| Computer Aided Drawing |

|

|||||||||||||||||||||

| Project |

- Practice on Furniture Specific drawing

(2 Days)

|

|||||||||||||||||||||

The lessons for Auto CAD span two weeks of training. That is, from 9.00 a.m. to 5.00 p.m., with a 15-minute morning break, an hour-long lunch break, and a 15-minute afternoon tea break. Classes run from Monday to Saturday.

This course follows hands on competency based approach which combines classroom training with practical exercise training on Auto CAD. The program begins with theoretical foundations, covering Fundamentals of wood and wood based panels, Auto CAD software commands and application of it to create the furniture specific and detailed production drawing.

Certification includes a final project where learners create the design of a furniture specific product using Auto CAD .

Cost per participant or group pricing.

Product development and design using PYTHA

This short course equips learners with essential skills to use Pytha software to create furniture specific drawing, they will gain hands-on experience to gain proficiency in 3D modelling, creating BOM, and detailed production drawing.

Key Competencies:

- Wood and Wood based panels knowledge– Understand wood and wood based panels properties behaviour and application.

- Understand the interface of the software and commands to create the 3 D models such as cabinets, tables chairs etc.

- Participants will be able to create the detailed production drawing and generate the BOM.

- Participants will be able to transfer the Pytha file to different drawing formats.

Career Pathways:

- Draughtsman

- Designer and 3D visualizer

Eligibility Criteria:

Working experience in Furniture Industry

| Module | Sub-module & Day(s) | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Industrial Practice |

- Fundamentals of wood and wood based panels

- Fundamentals of Drawing and Projections >

(1 Day)

|

|||||||||||||||||||||||||||

| Industrial Practice |

|

|||||||||||||||||||||||||||

| Project |

- Project on Furniture Specific drawing

>

(3 Days)

|

|||||||||||||||||||||||||||

The lessons for Pytha 3D CAD span two weeks of training. That is, from 9.00 a.m. to 5.00 p.m., with a 15-minute morning break, an hour-long lunch break, and a 15-minute afternoon tea break. Classes run from Monday to Saturday.

This course follows hands on competency based approach which combines classroom training with practical exercise training on Pytha 3D CAD. The program begins with theoretical foundations, covering Fundamentals of wood and wood based panels, Pytha software commands and application of it to create the furniture specific and detailed production drawing creating BOM and nesting plan.

Certification includes a final project where learners create the design of a furniture specific product using Pytha 3D CAD.

Cost per participant or group pricing.

Key Competencies

The program at the Faculty of Woodworking Skills focuses on a complete framework towards all the areas of competencies required to become a successful professional in the woodworking industry. For each area of competency individual competencies are defined which brings holistic skills like:

- Safety Awareness Skills

- Designing and Planning Skills

- Product Manufacturing Skills

- Problem-Solving Skills

- Technical Knowledge

- Installation and Service Skills

How BSDU is better than any other Skill University?

One Student-One Machine Concept

ensuring personalized, hands-on learning

Expert Faculty

from Switzerland

Swiss Dual System

combining theoretical knowledge with extensive practical application

Holistic Development

focusing on developing both technical skills & soft skills

Paid Industry Internships

every alternate semester to eligible students

Industry-Standard Training

on latest machinery & equipment

Multiple Entry & Exit System

at Certificate, Diploma, Advanced Diploma, and levels

Strong Industry Partnerships

ensuring relevant training & excellent placement opportunities.

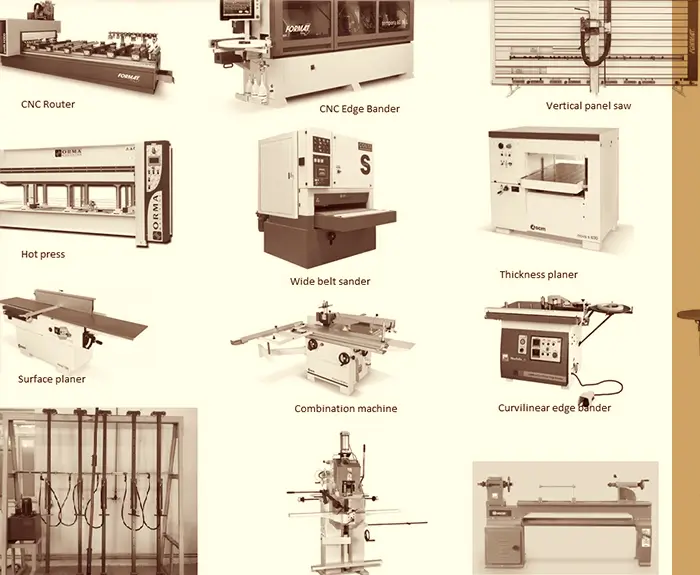

Infrastructure &

Equipment

The Faculty offers the latest machinery imported from Italy, Austria, Switzerland, Japan, etc. and has well-equipped labs:

1. Stationary Machines- Panel Saw

- Surface planner

- Thicknesser

- Band Saw

- Mortiser

- Multi Boring

- Vertical Panel Saw

- Spindle Moulder

- Combination Machine

- Wide belt sander, Edge Sander

- CNC router from Felder

- CNC Edge Band from Felder

- Routers, Circular saw, Planner, Biscuit joiner, Domino, Climax joiner, Oscillation saw etc.

Scope/Future Prospects

The woodworking industry presents a promising future for professionals, with the Indian furniture industry being large and dynamic in the world. As the demand for skilled professionals in woodworking industries grow, there is a wide range of opportunities for career growth and development in this dynamic industry.

The key skills taught in the program culminate into meaningful professions in the woodworking industry. Graduates are prepared for careers as

- Furniture Designers

- Quality Controllers in Furniture

- CNC Router Specialists

- Woodworking Entrepreneurs

- Production Advisor

- Production Manager

- Supervisor

- Production planner

- Production Engineer in NPD department

Internship & Placements

Department of Workplace Training

The Department of Workplace Training & Placement (DWTP) at Bhartiya Skill Development University (BSDU) connects students with recruiters, ensuring a match between their mutual aspirations.

Our Expert Faculty

The Faculty of Woodworking Skills Education is committed to providing students with a holistic approach to skill-based education that prepares them for rewarding careers in Woodworking Industry. The faculty and learning resources create a learner-centric environment that emphasizes practical learning, action competence, and real-world applications, supported by outstanding faculty and national and international academic partnerships. Our students have proudly represented India in the International Skill competitions held in Switzerland and Russia.

The Faculty believes in enjoyable teaching-learning under the watchful eyes of Swiss and Indian trainers, through an ultra-modern workshop facility.

I extend a warm welcome to all the students joining the Faculty of Woodworking Skills Education.

Abhay Sharma

Dean, Faculty of Woodworking Skills

Abhay Sharma

Chief Trainer & Dean

Kumar Shanu Sharma

Trainer-I

Kamlesh Bagra

Trainer - I

Ashish Tatwal

Trainer – II

Jeremias Pellaton

Project Manager

Alumni

Mahendra Sharma

- Godrej & Boyce Mfg. Co Ltd

- Year of Passing: 2020-2023

- Salary - Rs 41,000/Month

Jay Kishan Suthar

- Furniture and Fitting Skill Council

- Year of Passing: 2020-23

- Salary - Rs 35,000/Month

Jatin Pal

- Govik Industries Pvt. Ltd.

- Year of Passing: 2018-21

- Salary - Rs 65,000/Month

Himanshu Jangid

- Rockworth international

- Year of Passing: 2020-23

- Salary - Rs 60,000/Month

Bhim Singh

- Modi Furniture

- Year of Passing: 2018-21

- Salary - Rs 45,000/Month